The experimental structure in the Laboratory for Structural Dynamics

In the laboratory for structural dynamics of the I4S at the HTWK Leipzig, a test structure was set up which is similar to the experimental object in the open fieldt (for more information on requirements and test structure see here).

The 6 m long test structure is clamped horizontally. An important feature is that the ambient conditions (e.g. temperature) can be set in a controlled manner.

Production of the test fixture

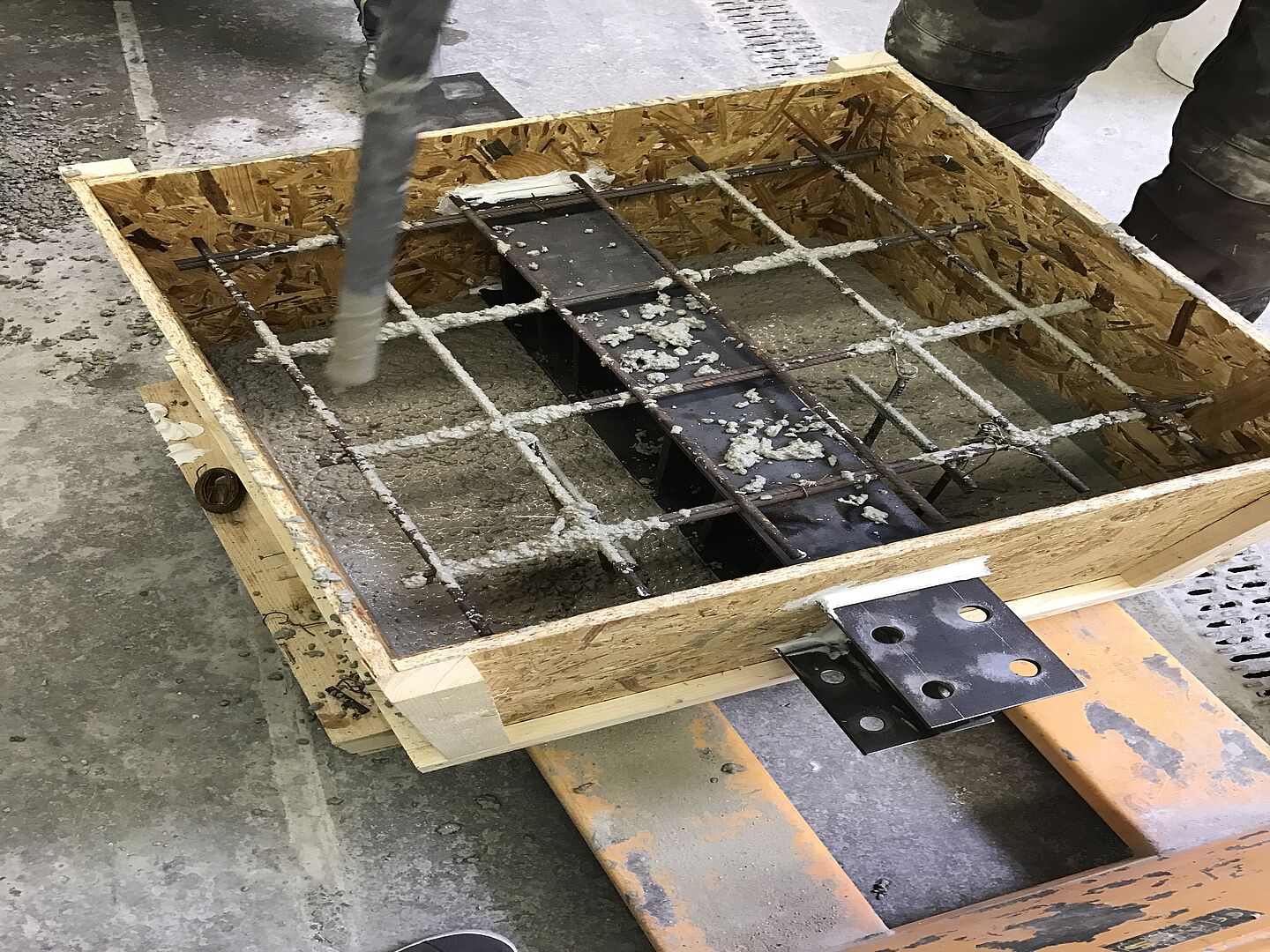

The Laboratory for Structural Dynamics has a foundation that is decoupled from the environment. This minimizes external influences. The test structure was attached to a reinforced concrete block with bolted connections to minimize bending. A steel segment with a cross-section of IPE200 was concreted in to create a restraint (see Figure 1). The concrete block, manufactured in the concrete technology laboratory at the HTWK Leipzig, consists of high-strength concrete with a calculated compressive strength of fc;cube=75 N/mm².

Fig. 1: Production of the clamping made of high-strength, reinforced concrete in the concrete technology laboratory, HTWK Leipzig

Construction of test structure

In order to ensure full-surface force transmission, the test restraint was aligned on concrete blocks with a mortar leveling layer. It was secured against tilting using braced crossbeams (see Figure 2), which were fastened to Halfen rails using threaded rods (diameter ø16). The six 1 m long steel modules (cross-sectional profile IPE 200) were then attached to the clamping system with bolted lugs (pretensioning force 180 Nm).

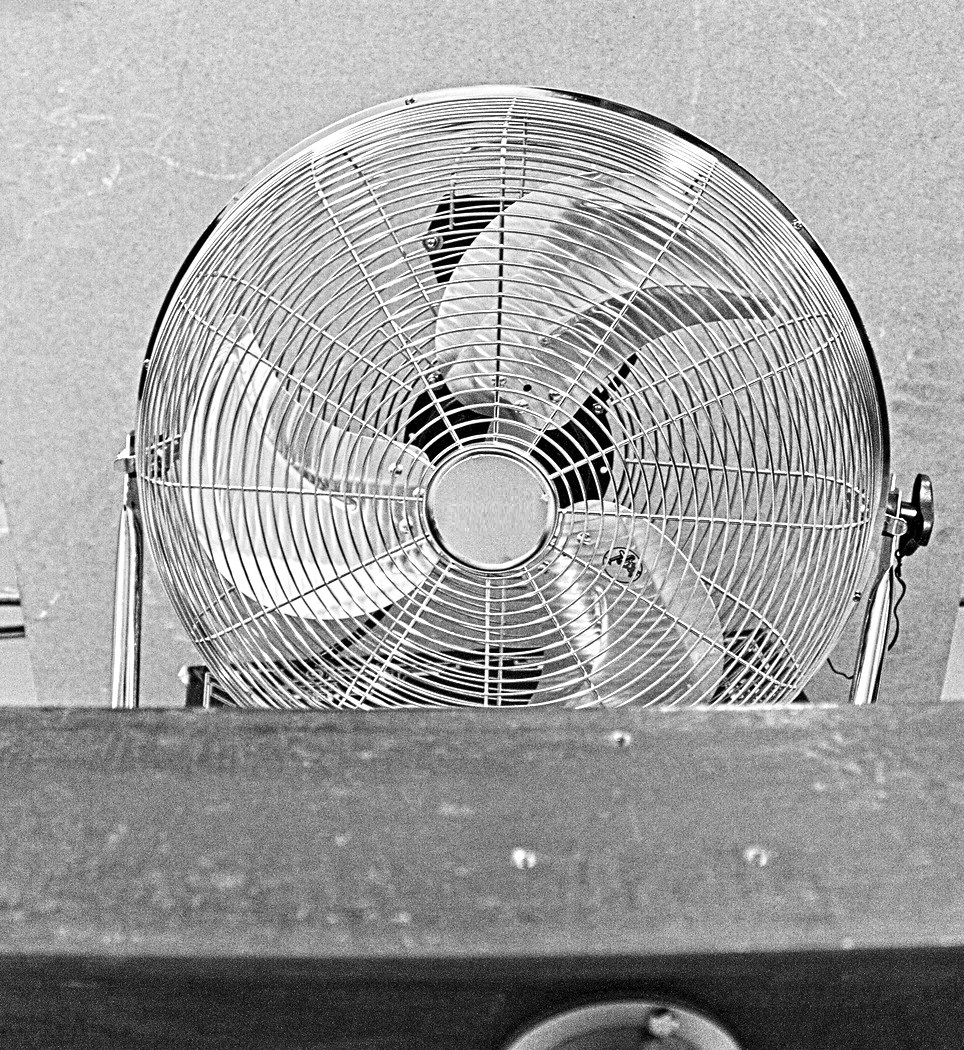

Experimental setup

The measurement technology used corresponds to that used in the open field: 24 uniaxial acceleration sensors (Figure 3; 393A03, PCB Piezotronics). To simulate the situation outdoors, wind excitation is provided by fans (see Figure 4). This made it possible to set up a test structure in the laboratory comparable to the experimental field on the roof of the Nieperbau. This allows environmental conditions to be changed in a controlled manner. A series of tests were carried out at the I4S to verify the methods developed, which could be used for publication.